Seals Made of High-Performance Materials for the Food and Beverage Industry

News Fair news

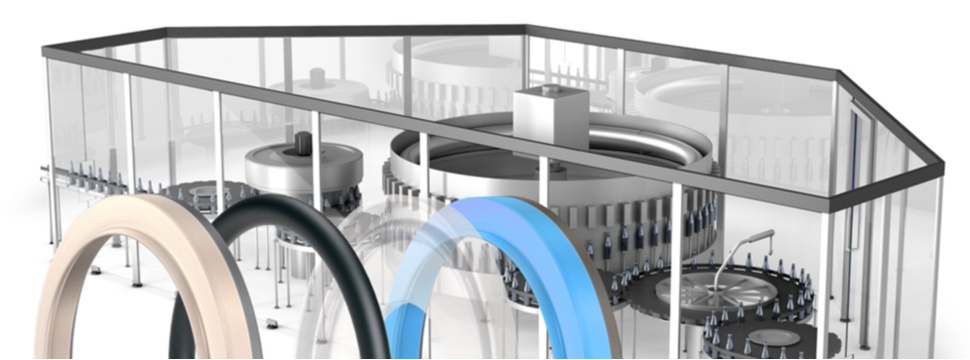

Freudenberg Sealing Technologies will be presenting food compliant materials and seals at drinktec 2022 trade show from September 12-16 in Munich (Germany) in Hall B3.249. These products and materials are certified to meet the latest regulatory requirements for food contact materials and address the temperature, media resistance and CIP/SIP needs prevalent in the food sector. The following materials will be profiled at the show.

Peroxide-crosslinked fluoroelastomer 75 FKM 239961

Among Freudenberg Sealing Technologies materials being introduced at the drinktec this year is a new peroxide-crosslinked fluoroelastomer material (75 FKM 239961). This material is compliant with the current regulatory requirements for food contact materials and is suitable for use in temperatures ranging from -25 °C to + 200 °C. The material offers outstanding resistance to various product- and cleaning media.

High-quality fluoroelastomers (FKMs) are used throughout the process industry. In the food and beverage industry, the materials are used in environments that involve high operating temperatures. FKM is also the first choice in environments where aggressive media can degrade other materials such as EPDM and HNBR. For example, fluororubber is recommended in the beverage industry for contact with pure citrus juices or dairy products. The material is also suitable for use with aromatic oils such as orange or hop oil. Currently, Freudenberg Sealing Technologies manufactures O-rings from fluororubber. In the nearterm, the company will also begin producing customer-specific parts made of 75 FKM 239961.

Durable polymers for high performance

Another company material that will be on display at the drinktec 2022 trade show is the high-performance polymer Quantix® 77-8FG. This unique Freudenberg Sealing Technologies polymer is characterized by good tribological properties, excellent impact resistance and a long service life. This makes it particularly suitable for sealing and wiper elements, guide and bearing elements, and anti-extrusion elements in high-pressure applications.

Quantix 77-8FG also shows an excellent chemical resistance and good permeation properties. As a result, the high-performance polymer can be a competitive alternative at operating temperatures of up to +110°C to PTFE materials which are usually much more expensive.

High-performance materials for extreme requirements

Simriz® perfluoroelastomers (FFKM) have the highest degree of fluorination and make excellent high-performance material choices in food and beverage applications. Freudenberg Sealing Technologies has developed three Simriz® compounds -- 75 Simriz® 494, 75 Simriz® 484 and the white 75 Simriz® 38581 – to meet demanding conditions in both static and dynamic applications.

These materials can withstand high temperatures of up to +230 °C as well as aggressive and highly concentrated media such as acids, alkalis (incl. CIP/SIP media), organic solvents and aroma concentrates. Simriz® perfluoroelastomers successfully manage extreme environmental conditions that challenge other materials such as EPDM and FKM. Simriz® materials are suitable for use in both polar and non-polar media.

Product line for hygienic equipment in the process industry

The process industry places tremendous demands on its sealing components. Components must not only comply with hygiene standards, but also have a high degree of cleanliness and above-average resistance to media, heat, and pressure. To meet these challenges, Freudenberg Sealing Technologies will be presenting its hygienic equipment portfolio for process industry applications at the drinktec 2022 trade show.

The product portfolio includes the Hygienic Pressure Seal and Hygienic Forseal, which are made from the high-performance PTFE Quantum®. The product line also includes dead space-free radial seals for face valves, rotary shaft seals, Hygienic Usit® rings and aseptic O-rings. Shaft seals and butterfly valve seals complete the portfolio.

Extruded round cords and profiles made of proven EPDM material

Freudenberg Sealing Technologies manufactures large-scale frame, cover and other seals from impact-vulcanized extruded material that is suitable for the process industry. Custom seal designs for specific applications are also available.

The sealing profile is cut to any length and joined to form a closed sealing ring. In addition, the profile cross-section can be designed very freely since mold removal is unnecessary. For example, complex cross-sections with many sealing lips or even with cavities can be produced. All seals are certified according to FDA and EG (Reg.) 1935/2004.

The sealing experts at Freudenberg Sealing Technologies will be available to answer any further questions during drinktec in Munich (Germany) from September 12 to 16, 2022 in Hall B3.249.