RimoMalt opens a new dimension for craft malting

News General news

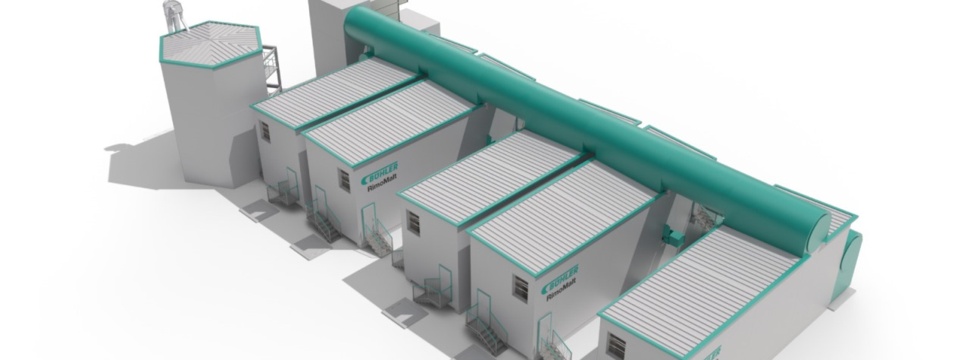

Bühler’s new RimoMalt is the solution small and mid-sized craft beer producers have been waiting for. It offers unprecedented flexibility – and brings investments down to an all-time low. Finally, craft producers can start off with very small batch sizes with an output that is easily scalable from 1,000 to up to 17,000 tons per year thanks to its modular system.

In times of volatile markets, quickly changing consumer preferences and emerging niche tastes, the individually customizable RimoMalt is the answer to current challenges and malting trends. Breweries producing up to 1.1 million hectoliters annually will be able to fully produce their own malt for their beer, including the possibility to quickly increase their production as demands rise. Of course, established maltsters can profit too, if they wish to try new products and widen their special malt portfolios. Not to mention all other malt demanding brands from of distilleries to sweets and foods.

Start up in any place – while taking up less space

The new RimoMalt’s footprint is extremely low. In contrast to regular malting systems, it does not need an additional building as it is designed for outdoor installation from the start. Thereby, producers can stay in touch with local preferences and instantly react to taste changes. Or stay ahead of new urban trends: “Even in scarce downtown areas you can claim a unique positioning and provide or even create new tastes, no matter if you look at new aromas from different grains or special malts with darker colors. RimoMalt facilitates highest quality in any climate from hot and humid cities to ice-cold rural terrains,” says Johannes Kolb, Sales Manager for malting and brewing at Bühler. RimoMalt starts off quickly: Its current delivery time is approximately six months. Depending on the configuration, within 12 to 20 weeks of installation and start-up on site it is ready to run. Extra germinating-kilning units are installed while allowing full uptime as the existing units’ production stays unaffected. Extensions with intermediate modules take one week to integrate while only stopping the respective unit. And even raising the steep does not necessarily lead to downtime depending on its occupancy rate.

Amazingly basic: extending steeping volumes has never been easier

The fully insulated and cladded steep house starts at a volume of 16 metric tons. It can be upscaled in two steps to 32 and 56 tons simply by adding height-extending rings. The stairs are mounted next to the steeping unit to reach the top. Easy access grants effortless control of the grain elevator to maintain both process and quality control. The functionality is kept as basic as possible and ensures a smooth process with wet steep, dry steep and the final wet steep before pumping the steeped material to the germinating-kilning unit(s).

Germinating and kilning in one – meeting highest hygiene standards and process reliability

After steeping the product is gently pumped onto the floor deck inside the boxes of RimoMalt’s unique germinating-kilning unit. This one-of-a-kind combination of both processes reduces conveying steps and provides for greater malt quality. Every unit is equipped with its own turning-, loading-, and unloading system that levels out the product for uniform germination and kilning of all kernels. This even layer on a perforated deck creates consistent air flow throughout the process. As an important addition to the flexibility, each box has a decentralized axial germination fan and its own cooling at the unit’s starting module. This design allows for individual operation of each unit as well as RimoMalt’s tailored extension options. The units can be scaled up independently in eight-ton steps with quickly installed intermediate modules between starting and end module. This feature is unique in the market. “For the first time it is possible to start a production with very small batch sizes and extend each box individually at any later stage. RimoMalt can facilitate various portfolio demands simultaneously by producing different special malts at the same time within a full 24-hour batch cycle,” says Johannes Kolb.

Highest efficiency in the malting world

Malting processes are already exceedingly high in efficiency. Nevertheless, RimoMalt still sets the bar higher as the most efficient malting solution in the market. One reason is the possibility to combine various heating systems in the heating unit, which supplies hot air for the centralized radial kiln fan. Furthermore, a glass-tube heat exchanger is integrated in the heating unit. Here, the heated revert air is reused to preheat the incoming fresh air. This is just one of the many examples how Bühler reaches optimal efficiency in every detail – reassuring Bühler’s sustainability goal for all its clients: to reach a 50% decrease of waste as well as energy and water consumption by 2025. And this includes to even identify aspects beyond Bühler solutions: the small footprint and flexibility of RimoMalt enable more local production and grain use which, in turn, decreases emissions in logistics and supports small ecofriendly grain suppliers.

Future-driven solutions and services

With the new RimoMalt, small and mid-sized breweries can start a bright malting future – making best use of its automation system Mercury MES (Manufacturing Execution System). Web-based and working on all devices, it offers a seamless data exchange between all systems for optimal workflow. This can further include a whole high-quality scheme in which the new RimoMalt can be embedded: from whole grain handling, water saving washing, safe sorting to truck loading, or processes like roasting and caramel malt production. And Bühler’s Application Center in Beilngries, Germany, is ready to help brands in research and development for process optimization along with creating new tastes and trying out new malting and brewing ideas tailored to any market around the globe.