Verallia inaugurates its first 100% electric furnace: a world first in the food glass packaging industry and a major step towards decarbonizing the sector

News General news

Verallia, the European leader and third-largest glass packaging producer in the world, inaugurated the first 100% electric furnace at its Cognac plant. This technological innovation, which reduces CO2 emissions by 60% compared to a traditional furnace, is part of the Group’s ambitious decarbonization strategy and marks a decisive step towards a more sustainable future for the glass industry.

In the face of the climate emergency, Verallia has been committed for several years to decarbonizing its activities. Through a clear and robust CSR roadmap, the Group aims to reduce its emissions (scopes 1 and 2) by 46% by 2030 compared to 2019.

As part of this strategy, the Group announced in 2021 the construction of its first 100% electric glass furnace with an investment of €57 million, marking a major milestone towards more sustainable production.

A world first dedicated to the decarbonization of the glass industry

The result of a strategic partnership with Fives, an international industrial engineering group of French origin, this furnace represents a breakthrough in the production of flint and extra-flint glass. With a daily capacity of 180 tons, equivalent to 300,000 bottles, it reduces CO2 emissions by 60% compared to a traditional furnace.

This innovation is aligned with the Group’s goals of drastically reducing its carbon emissions through an ambitious investment policy aimed at transforming the technologies, resources, and industrial equipment used at its sites.

Patrice Lucas, CEO of the Verallia Group, expressed delight with the completion of this project: “This 100% electric furnace is at the intersection of our sustainability, innovation, and development challenges. It is a strong symbol for Verallia, fully illustrating our CSR roadmap and our ambitious investment plan to optimize energy consumption at our sites and develop low-carbon furnaces. It is also a major step forward for the food glass packaging industry, and we are very proud to be pioneers in this area.”

A showcase of French excellence serving our clients

Thanks to the availability of decarbonized energy near the Cognac site and the support of ADEME as part of the ‘France 2030’ plan, the Group’s first 100% electric glass furnace was inaugurated in Cognac, placing Verallia at the forefront of the global glass industry in terms of decarbonization.

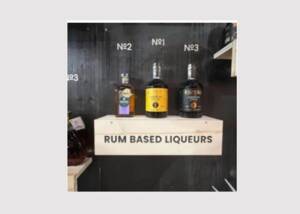

This new electric furnace in Cognac will produce flint glass bottles, particularly for flagship Cognac brands. It will contribute to the international reputation of French know-how and lifestyle, enhancing the competitiveness of a centuries-old industry rooted in the Charente region.

Pierre-Henri Desportes, General Manager of Verallia France, added: “Our new electric furnace in Cognac perfectly illustrates our commitment to our clients and our region. It enables us to concretely support our partners, especially the major Cognac houses, in reducing their carbon footprint. It is also a demonstration of our ability to eco-design sustainable packaging while maintaining premium quality. This significant investment strengthens our local presence and confirms our role as a responsible economic player in the region.”